Modernization of production

The history of the modernization project

In 2004, an international conference BIO-2004 program experts BII, Ltd. "research company" Aberkeid "" and OOO PO "Sibbiofarm" took part in the business program of the conference and discussed the possibility of joint work on the modernization of the software company "Sibbiofarm." The main objective of the project was to create a plant-based Berd biologicals modern innovative biotechnology company.

The modernization program includes full automation of technological processes, replacement of laboratory and production equipment, lower costs for energy, steam and water, regular monitoring of the market, to build a system of distribution and sales, the establishment of a research center at the company's training and development of staff.

The results of modernization of production

Modernization of the main production

ASU-TP

The modern enterprise is impossible to imagine without the automatic control and management. On Software Ltd. "Sibbiofarm" automation system was installed by Siemens. The project carried out a Novosibirsk company "Sigma Pro".

The operator has to monitor the computer can control the fermentation process, sterilization and creation of finished product shape. In automatic mode, the system notifies all deviations from the prescribed norms of the process and allows you to collect and analyze information.

Water cooling system

To maintain optimal temperatures during microbial synthesis and concentration of native fluids is necessary to ensure efficient cooling equipment and economical use of recycled water and energy. As part of the modernization program were purchased and installed two chillers.

Shop liquid enzymes

Commissioned shop for the production of liquid forms and granular forms of the enzyme. This enables the software company "Sibbiofarm" to produce all forms of enzyme products at the request of customers. The use of modern filtration systems significantly reduces the cost of electricity, & nbsp; at the same time maintaining high enzyme activity. Modern granulators allow you to create a product for even the most demanding customers. Granulated form less allergenic, more convenient for use in the feed industry.

Central production laboratory

Normal functioning of the production is impossible without maintaining and improving his own museum strains, optimization and control of the production process at all stages of seed development for fermentation. & Nbsp; As part of the upgrade was a complete reconstruction of all rooms and Communications Laboratories, bought new equipment and furniture. Laboratory specialists have been trained in the program GLP and GMP. Modern equipment has accelerated the implementation and accuracy of analysis at all stages of production, reduced the level of manual labor and give additional opportunities to improve the technology and conduct scientific research. & Nbsp; numerically - & nbsp; 40 specialists. The total area of & nbsp; more than 500 m2.

Laboratory OTC

Laboratory Quality Department & nbsp; controls all stages of production from the incoming inspection of raw materials to the finished product acceptance control, which allows the company and its customers to be confident in the quality and compliance of & nbsp; all settings & nbsp; product standard documentation. Laboratories are equipped with new instruments and equipment.

Laboratory Chromatography

LLC PO "Sibbiofarm" uses various types of chromatographic equipment for research and quality control.

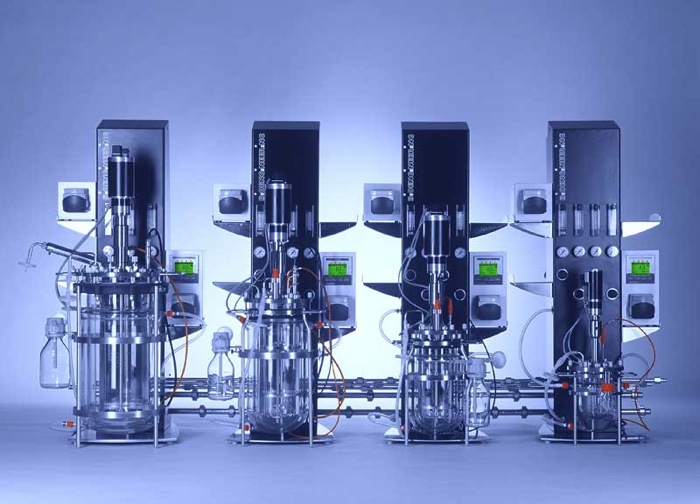

Pilot production

According to the results of the tender LLC PO "Sibbiofarm" decided to purchase pilot production equipment of the Swiss company "Bioengineering AG." This unique pilot equipment that allows you to scale the technology from the laboratory to the industrial level, to produce small batches of very pure drugs & nbsp; and experimental batches of products for testing and testing. LLC PO "Sibbiofarm" also plans to provide services for contract manufacturing and optimization of process parameters & nbsp; on the pilot equipment.

Energetics

Berd biologics plant was founded in 1957, was put into operation in 1963. At the same time, it has been put into operation and the steam boiler. & Nbsp; By the time the project of modernization and the transition to private ownership of the enterprise equipment physically and morally obsolete. Therefore, it was decided a full-scale modernization of the entire energy complex. Microbiological production of & nbsp; - it is energy-intensive production, the company's competitiveness, and control & nbsp; for the costs directly depend on the energy. Built a new transformer station, purchased a new steam turbine (Proletarian Plant), compressor (Atlas Copco), installed new pipes with modern insulation.

Training

The company's management attaches great importance to training and ongoing training of personnel. Without the exchange of experience, participation in international scientific and business conferences can not save the company's competitiveness.

Thanks to the support program BII (Industrial Bioinitsiativa) and managers of the American Center for Scientific Research (CRDF) & nbsp; The company's specialists have been trained in the company Diversa, attended workshops in Russia and abroad on international standards of laboratory work and research, regularly participate in international conferences, such as the BIO Convention.